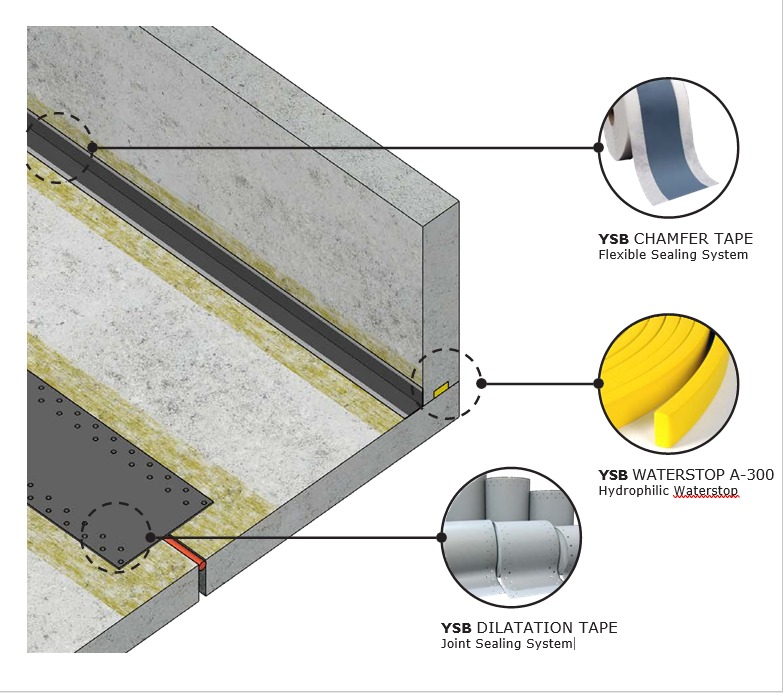

The carrier of the YSBFLEX Pah Band with high elasticity is felt and the middle part is made of elastomeric resin in the desired colors (RAL, PANTONE). Thanks to its felt carriers, it complies very well with liquid waterproofing products applied by driving and creates a seamless insulation layer.

The carrier of the YSBFLEX Pah Band with high elasticity is felt and the middle part is made of elastomeric resin in the desired colors (RAL, PANTONE). Thanks to its felt carriers, it complies very well with liquid waterproofing products applied by driving and creates a seamless insulation layer.

Usage Places

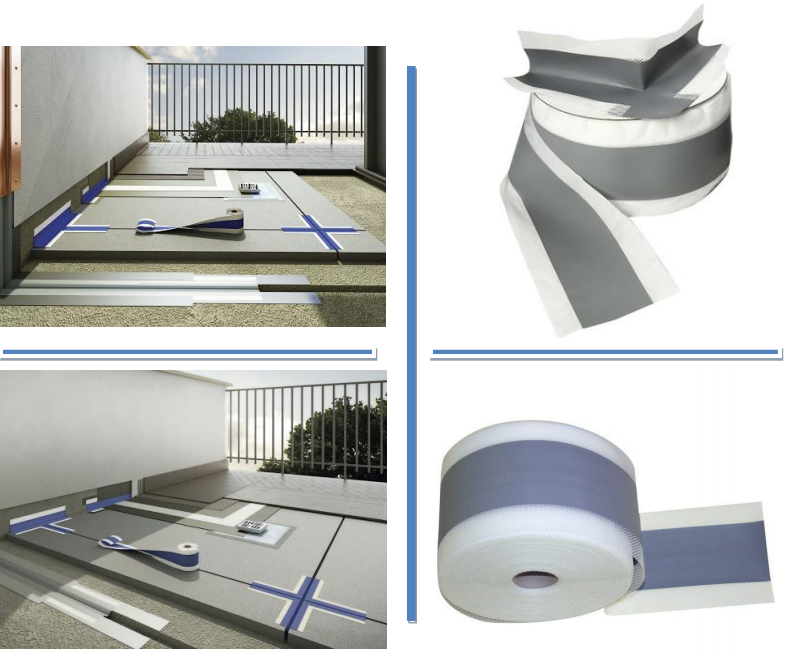

• Thanks to its high alkali resistance, it is compatible with cement-based products applied outdoors such as terraces and balconies.

• In the insulation of balconies and terraces,

• It is used in the insulation of wet areas.

Advantages

• Easy to apply.

• Provides a continuous insulation.

• It is resistant to many chemicals.

• Resistant to ozone and UV.

Method of Application

Preparation of Application Surface:

• The application surfaces must be dry.

• Surfaces should be clean, solid, and free from carrier and free particles.

• Layers that reduce adherence such as oil, grease, dirt, paint, cement grout, rust, mold oil, salt efflorescence should be thoroughly cleaned before application.

• The surface should be roughened by mechanical methods in areas deemed necessary.

A suitable waterproofing product is applied on both sides of the joint or crack (the middle part is approximately 5 cm empty) and YSBFLEX tape is laid on it before it dries. It should be ensured that the felt parts are pressed with a roller or brush and that it is in full contact with the waterproofing layer at every point. Care should be taken that there is no pot formation on the band surface. After the waterproofing product dries, a second layer should be applied on it and care should be taken to keep the felt part between the two layers in a leak-proof way. Care should be taken to ensure that the middle part of the tape does not stick to the insulation layer and remains idle, the tape will thus bridge the movements of the structure. Cracks wider than 3 mm should be filled with a suitable mastic before application.

Technical Data

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* Istanbul Technical University Report No: 221a / 09.03.20l6

Packaging: White Box in Parcel (10 Rolls Each Roll 50 m / tulle) 500 m / tulle

Shelf Life: It is 24 months unopened under suitable storage conditions (in a dry and cool environment, in its original package).

Non-Woven Fabric

Polyester Fabric