YSB FOAM

Fire Retardant Acoustic Foams Open-cell, impregnated polyurethane foam for acoustical and thermal insulation

Fire Retardant Acoustic Foams Open-cell, impregnated polyurethane foam for acoustical and thermal insulation

Ysbfoam is an open-cell polyurethane-based material impregnated with inorganic minerals produced for acoustic, thermal, water and dust insulation. Shows high performance in fire resistance tests. Ysbfoam does not melt and flow under flame. It is not affected by the bacteria and does not contain them. It keeps its form during fire without changing shape. Its insulation properties against sound, heat, liquid and dust are higher than similar products. These products have been selected after many tests conducted in canopies by the companies. Acoustic performance of each product varies according to the size and shape of different canopies.

Physical Specifications

Nominal Density Range: 75-100 kg/m3

Nominal Hardness Range: 120-108 Newton

Elongation at Break: Not less than %90

Tensile Strength: Not less than 70 kpa

Operating temperature: -40°C,+110°C

Colour

Black

Summary of Fire Resistance Test

BS 476: Part 6 – Surface flame propagation: The ratio of surface propagation of flame is very low – Class 1, Part 7

The insulation that meets the standards specified in BS 476: Parts 6 and 7 above was rated as ‘Class 0’ according to the United kingdom Building Regulations.

BS 476: Part 7 – Fire Performance: Class 0

ASTM D – 2863 Oxygen Index: 45%

Practices To Be Performed

The back of the product is self-adhesive.

Product is provided in composite form with lead or polymeric barriers and damping plates.

⦁ – PU film (surface protective film): 35 (micron) polyurethane film, resistant to grease, water and lubricating.

⦁ – PSA: Self-adhesive, resistant to up to 80°C. Networked Modified Acrylic.

Installation

Adhesive systems used in canopies.

⦁ Water-based/Solvent-based adhesives

Ysbfoam products can be easily installed on any clean surface (concrete, plastic, wood, metal, plastic, etc.) by using a solvent-based glue. The sheets or rolls can be easily cut with a utility knife when required. Sheets can be bonded independently of each other or side by side for the best acoustic performance and a nice view.

⦁ Self-adhesive tapes

Self-adhesive tapes can be fixed at the back of the products. So, it becomes quick and easy to apply, it is also safe and there is no risk of inhalation of glue.

⦁ Non adhesive bracket

PACKAGING

In sheets: 2000 mm x 1000 mm

In rolls: Thickness: 6 mm, Dimensions: 1×30 meters Thickness: 10 mm, Dimensions: 1×20 meters Thickness: 15 mm, Dimensions: 1×15 meters Thickness: 20 mm, Dimensions: 1×10 meters Thickness: 25 mm, Dimensions: 1×10 meters

All the products are packed individually with polyethylene film.

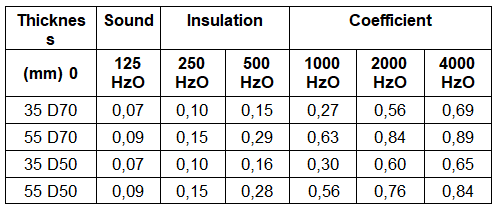

Acoustic Performance

Comparison Table For YSB FOAM and 30D Acoustic Foams

Fields Of Applications

⦁ Bus Installation

⦁ Truck Installation

⦁ Train Wagon Installation

⦁ Boat Installation

⦁ Automobile Installation

⦁ Studio Installation

⦁ Generator Installation

⦁ Container Installation

⦁ Compressor Installation